Technology

Owing to rapidly evolving technology in the printing industry, the time taken to complete big printing jobs has been drastically reduced since we first entered the scene. Building on the capacity that technology has empowered us with, we are able to handle huge orders and to deliver with efficiency and remarkable speed. As printing becomes quicker and more responsive, so do we. The difference is that we go the extra mile, alongside you, and provide great solutions that won’t hurt your budget.

Our Story

Our story began in 1991, when father and son team J Kalyan and A Kalyan started operating with a single full colour printing press and table rewinding machines. With only three staff members, the company focused on timely delivery and customer satisfaction. This setup prevailed until 1995, when R. Kalyan assumed responsibility for the running of the company and Elite acquired its second label printing press. In response to our dedicated service and reliable delivery, customer demand had grown significantly and continued to rise until 2002, when we purchased our third label printing press. On to 2005, when we welcomed our first automatic rewinding machine.

Growth

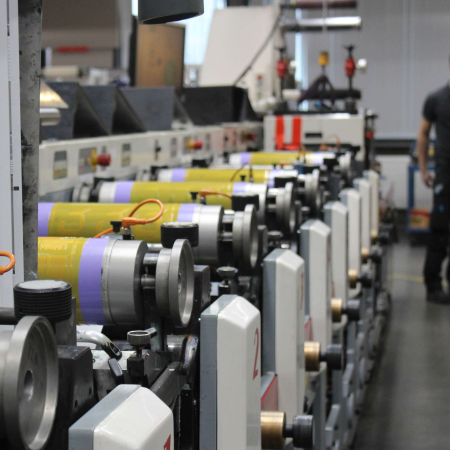

Although we have grown in experience and in capacity (we now employ 18 staff and run six full-fledged flexographic printing presses), we have kept our operations lean and agile, allowing us to respond speedily tour client’s need and schedules. We have also chosen to not change our dedication and personal interaction with our clients. Our production technology has improved over the years, while our approach to customers and suppliers has remained the same.

Future Developments

As time progresses and technology improves so do we. We aim to keep up with latest manufacturing processes and technology where ever possible. This ensures we keep on providing our customers with improved products and quality.

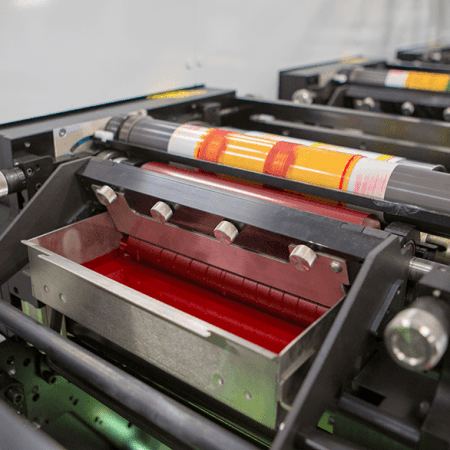

Process

We utilise the flexographic printing process, one of the fastest growing conventional printing processes famed for its ability to produce quality words and images across a wide range of surfaces and materials. This means that we can print on a wide array of substrates, for example foil, plastic film, board, paper, cellophane, polyester and polypropolene. Because the flexographic process can be used to print on such a wide variety of materials, it is widely acknowledged as the best graphic arts reproduction process for package printing. So, for those wanting to make a lasting, quality impression, our labels leave an indelible mark that won’t fade or wash away.